Our solutions range from feeding individual parts to packaging finished products, using inspection systems to ensure quality controls of your product.

Production can be monitored in real time and data saved in your control. The automotive industry is a very dynamic and demanding industry, requiring flexible and reliable production equipment.

CG AUTOMATION adapts quickly to meet these needs: providing a Service of Value to its processes, which distinguish us in reliability, Responsibility and commitment to the client.

DEVELOPING PRODUCTION ASSEMBLY MACHINES WITH IMPLEMENTATIONS SUCH AS:

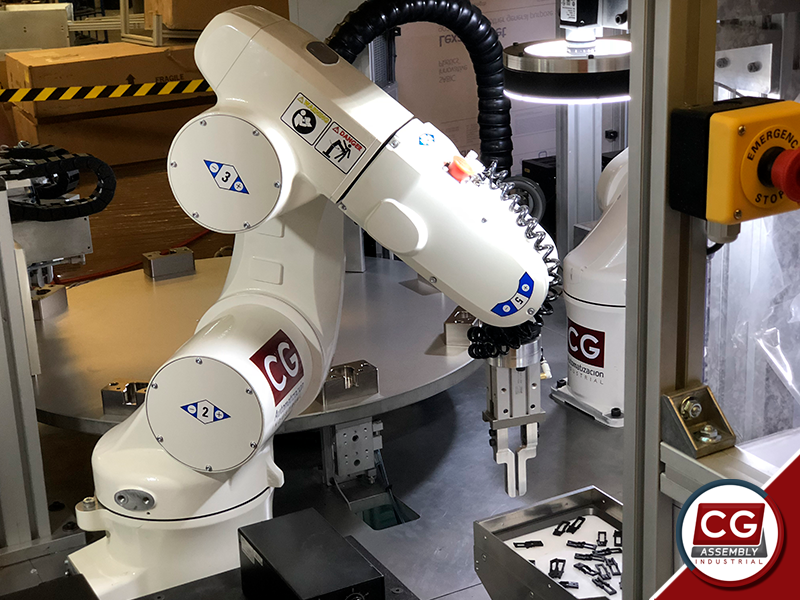

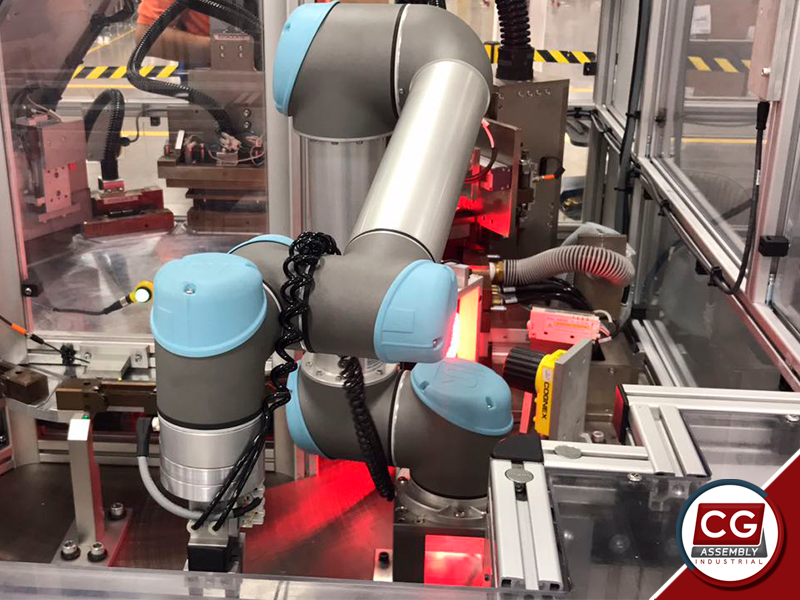

Robotic assemblies.

Assemblies with Pick & place.

Welding Assemblies

(Laser, Ultrasonic, Conventional).

Ensemble with glue and hot metal.

Robotic assemblies.

Part Feeding Technologies:

- Anyfeeder Robotico5

- Bolw feeder.

Material dispensers.

Vision Systems.

Torque Systems.

Test Stations:

- Electrical

- Mechanical

- Functionality

- etc.

Monitoring of components and parts.

Marking and reading of parts

(3D, Laser, bars, label).

Curing of parts

(Ultraviolet, Heat, Air, time, etc).

Material Handling.

Cutting and sizing processes.

Traceability:

- Pallet ID

- Barcode

- RFI TAGs